Should be OK with XPS foam and few tabs (I played and placed some tabs, but don't exactly understand their placement).Ĭlarifications would be much appreciated. Vector graphics (dxf and svg) and 3D (stl) files can be imported and machined using Estlcam. should it work or not with quite thin wind trailing edge and no support below during the 2nd face ? Estcam contains CAM and CNC controller programs. VCarve, F-engrave, MakerCam, EstlCAM, MeshCam, P圜am or Fusion 360. For the second side, what is expected as of zeroing or stock placement to accurately mill the second face with the right reference ? BobsCNC Evolution 3 CNC Router Kit with the Router Included BobsCNC Evolution 3 CNC. Are there specific constraints on the piece to mill to be adequate for 2 sides milling ? I still cannot find data about the robustness of 3D printing. Rory wrote: you need to approach this differently - 3D print.

#Estlcam 3d carving plus

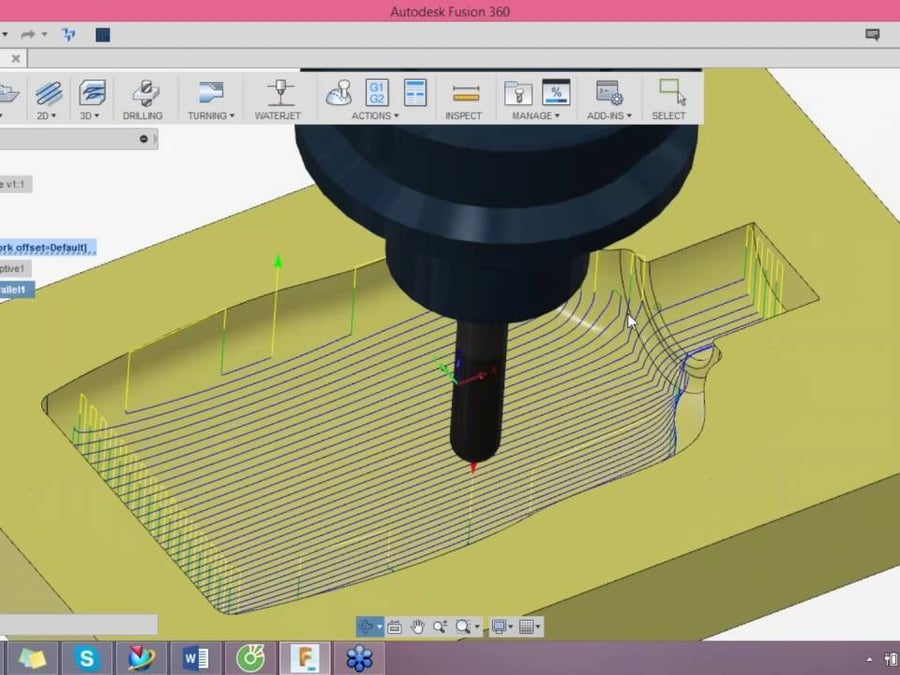

What is remarkable about Estlcam is the much lower learning curve and quick turn around times which a lot of hobbyists prefer compared to the bulk of other. Anyway, I could carve an upside-down pyramid (with large large steps) for, lets say, 70mm depth with a short-short-supershort cutting tool, yes The problem is the rigidity of all the machine plus the cutting tool. At 60 for a single license, Estlcam is truly a hobbyist friendly CAM software. does it leaves a border around the piece that acts as a support for the second side ? Estlcam lets you do 2D and 3D toolpath generation by cutting out all the complexities for a quick operation. Help to clarify how it is intended to work would be very helpful: I know and have 3D apps, I just wasn’t sure about pushing.

I have very limited access to the CNC, so I have to prepare everything on the computer before being able to run on the CNC. First, you would need to get, and learn a 3D modelling app, then you use another app ((MeshCAM, V-Carve Desktop, estlcam)) to translate the 3D file into G-code, and send to the x-carve via UGS, Chilipeppr, etc.

#Estlcam 3d carving how to

I however don't perfectly understand how to use this EstlCAM "2 sides milling" feature. And playing with the program, I saw that it can automatically generate CNC files for both sides.

It shall be milled on the 2 sides,ĮstlCAM seems to be a very interesting option to generate the G-Code from the stl (which seems not proposed in F360 for example). The wing core is 2500 mm x 200 mm x about 16mm XPS foam with foil shape. I'm thinking to building a composite RC glider with CNC milled foam core wings.

0 kommentar(er)

0 kommentar(er)